Process Cooling

Cooling You Can Count On

Fast and efficient installation of new air conditioning units. Our certified technicians ensure your system is properly installed for optimal performance Site assessment, equipment delivery air an complete installation.

Regular maintenance services to keep your air conditioning system running smoothly and for as efficiently, preventing an breakdowns and extending its lifespan Filter replacement, coil cleaning, refrigerant check, thermostat calibration, and system inspection air conditioning Upgrading your existing air conditioning system.

Your Comfort, Our Mission

Upgrading your existing air conditioning system to more energy-efficient models, helping you save on energy bills and reduce your carbon footprint Lubrication of moving parts, electrical connection inspection,

Energy assessment, old unit removal, new unit installation, and energy efficiency optimization a Advanced diagnostic services using the latest technology to detect and address issues in your air conditioning system before they become major problems

Air Conditioning & Heating Services

Comprehensive system scan, fault detection, detailed report, and recommended solutions. Tha Precision calibration services to ensure your air conditioning system is operating at its optimal settings for maximum comfort and efficiency

- Precision Installations

- FrostWave Duct Cleaning

- CoolCare Maintenance

- CoolFlow Inspection

- TempGuard Emergency

- FrostGuard Inspection

We help you with the dedication & affection

Thorough cleaning services to remove dirt, dust, and debris from your air conditioning system, improving air quality and system efficiency

How often should I have my air conditioner serviced?

It is recommended to service your air conditioner at least once a year to ensure it runs efficiently and effectively. Common signs include unusual noises, weak airflow, warm air instead of cool, and a sudden increase in energy bills.

What are the signs that my air conditioner needs repair?

It is recommended to service your air conditioner at least once a year to ensure it runs efficiently and effectively. Common signs include unusual noises, weak airflow, warm air instead of cool, and a sudden increase in energy bills.

How can I improve the efficiency of my air conditionin

It is recommended to service your air conditioner at least once a year to ensure it runs efficiently and effectively. Common signs include unusual noises, weak airflow, warm air instead of cool, and a sudden increase in energy bills.

What size air conditioner do I need for my home?

It is recommended to service your air conditioner at least once a year to ensure it runs efficiently and effectively. Common signs include unusual noises, weak airflow, warm air instead of cool, and a sudden increase in energy bills.

Categories

Downloads

Ask Question

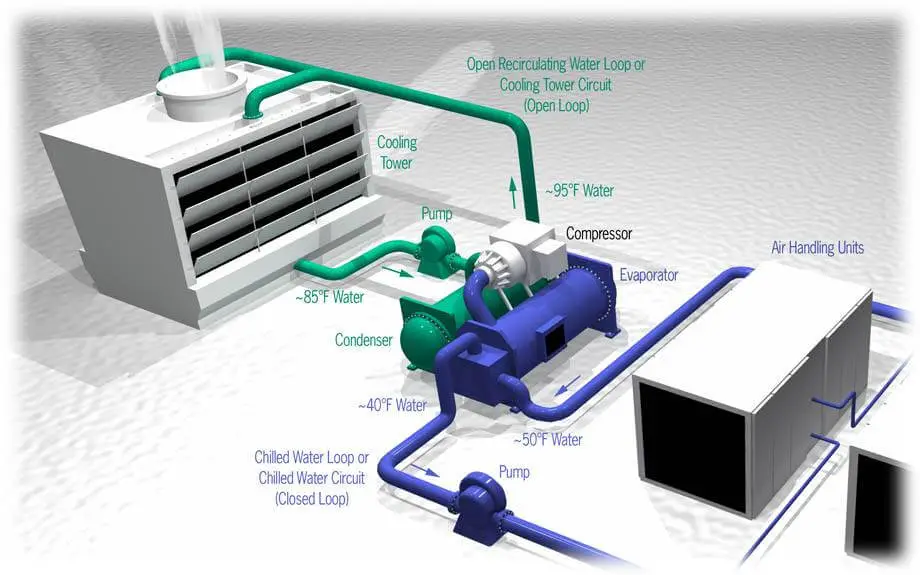

Process cooling in HVAC systems refers to the controlled removal of heat from industrial processes, machinery, and critical applications to maintain precise temperature conditions essential for operational efficiency, product integrity, and regulatory compliance. Unlike comfort cooling, which is designed for human environments, process cooling is specifically engineered to manage heat loads generated by manufacturing equipment, production lines, and chemical reactions. It plays a vital role in industries such as pharmaceuticals, biotechnology, food processing, semiconductor manufacturing, plastics production, and data centers, where temperature control is crucial for quality assurance and process stability.

How Process Cooling Works

Process cooling systems use refrigeration and heat exchange technologies to absorb, transfer, and dissipate excess heat generated during industrial operations. The core components of a process cooling system include:

- Chillers (Air-Cooled & Water-Cooled): These are the primary cooling units that use refrigerants to extract heat from the process. Air-cooled chillers release heat into the atmosphere, while water-cooled chillers transfer heat to cooling towers for dissipation.

- Cooling Towers: Used in conjunction with water-cooled chillers, these devices remove heat through evaporative cooling, improving efficiency in large-scale applications.

- Heat Exchangers: These facilitate the transfer of heat between fluids without direct contact, ensuring thermal stability in sensitive processes.

- Air Handling Units (AHUs): These regulate temperature, airflow, and humidity in controlled environments such as clean rooms and manufacturing facilities.

- HVAC Control Systems: Advanced monitoring and automation allow real-time adjustments to temperature, humidity, and pressure, ensuring optimal process conditions

Process cooling systems are critical in various industries. In pharmaceuticals and biotechnology, they ensure strict temperature regulation for drug production, vaccine storage, and lab environments. The food and beverage industry relies on process cooling for refrigeration, fermentation, and storage to prevent spoilage and ensure food safety. Semiconductor and electronics manufacturing require precise cooling to prevent overheating of microchips, wafers, and circuit boards. Plastics and chemical industries depend on process cooling to regulate temperature-sensitive molding, extrusion, and chemical reactions. Data centers utilize these systems to dissipate excess heat from high-performance computing and server operations. By incorporating energy-efficient technologies such as variable speed drives (VSDs), free cooling, and advanced refrigerants, modern process cooling HVAC systems reduce energy consumption, enhance operational reliability, and support sustainable industrial practices.