VAM Chillers

Cooling You Can Count On

Fast and efficient installation of new air conditioning units. Our certified technicians ensure your system is properly installed for optimal performance Site assessment, equipment delivery air an complete installation.

Regular maintenance services to keep your air conditioning system running smoothly and for as efficiently, preventing an breakdowns and extending its lifespan Filter replacement, coil cleaning, refrigerant check, thermostat calibration, and system inspection air conditioning Upgrading your existing air conditioning system.

Your Comfort, Our Mission

Upgrading your existing air conditioning system to more energy-efficient models, helping you save on energy bills and reduce your carbon footprint Lubrication of moving parts, electrical connection inspection,

Energy assessment, old unit removal, new unit installation, and energy efficiency optimization a Advanced diagnostic services using the latest technology to detect and address issues in your air conditioning system before they become major problems

Air Conditioning & Heating Services

Comprehensive system scan, fault detection, detailed report, and recommended solutions. Tha Precision calibration services to ensure your air conditioning system is operating at its optimal settings for maximum comfort and efficiency

- Precision Installations

- FrostWave Duct Cleaning

- CoolCare Maintenance

- CoolFlow Inspection

- TempGuard Emergency

- FrostGuard Inspection

We help you with the dedication & affection

Thorough cleaning services to remove dirt, dust, and debris from your air conditioning system, improving air quality and system efficiency

How often should I have my air conditioner serviced?

It is recommended to service your air conditioner at least once a year to ensure it runs efficiently and effectively. Common signs include unusual noises, weak airflow, warm air instead of cool, and a sudden increase in energy bills.

What are the signs that my air conditioner needs repair?

It is recommended to service your air conditioner at least once a year to ensure it runs efficiently and effectively. Common signs include unusual noises, weak airflow, warm air instead of cool, and a sudden increase in energy bills.

How can I improve the efficiency of my air conditionin

It is recommended to service your air conditioner at least once a year to ensure it runs efficiently and effectively. Common signs include unusual noises, weak airflow, warm air instead of cool, and a sudden increase in energy bills.

What size air conditioner do I need for my home?

It is recommended to service your air conditioner at least once a year to ensure it runs efficiently and effectively. Common signs include unusual noises, weak airflow, warm air instead of cool, and a sudden increase in energy bills.

Categories

Downloads

Ask Question

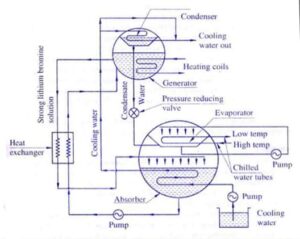

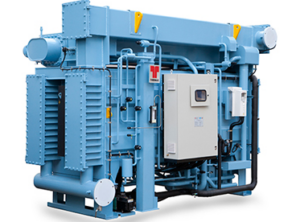

VAM (Vapor Absorption Machine) chillers are a type of refrigeration system used in HVAC applications that operate on the absorption refrigeration cycle, utilizing heat energy instead of electrical energy to generate cooling. These chillers are particularly energy-efficient and environmentally friendly, making them suitable for industrial, commercial, and district cooling applications. Unlike conventional vapor compression chillers, which use mechanical compressors, VAM chillers rely on a thermal compressor consisting of an absorber, generator, and solution pump to achieve refrigeration.

VAM chillers function through an absorption-based refrigeration cycle, involving the following key steps:

- Absorption: The refrigerant (water or ammonia) is absorbed by a chemical solution (lithium bromide or ammonia-water), creating a vacuum in the system.

- Heat Input (Generator Section): The weak absorbent solution is heated using an external heat source (steam, hot water, or gas) to release the refrigerant vapor.

- Condensation: The refrigerant vapor is cooled in the condenser and converted back into liquid form.

- Expansion & Evaporation: The liquid refrigerant undergoes expansion, reducing pressure and temperature, causing it to evaporate and absorb heat from the chilled water circuit.

- Regeneration: The weak absorbent solution is returned to the absorber to restart the cycle.

VAM chillers are classified into single-effect, double-effect, and triple-effect chillers, depending on the number of heat exchange stages and the efficiency levels. Single-effect chillers operate at lower temperatures (80-120°C) and have a Coefficient of Performance (COP) of 0.6-0.8, while double-effect chillers, which use high-temperature steam or gas (140-180°C), achieve a COP of 1.0-1.3. Triple-effect chillers, the most efficient type, use extremely high-temperature sources (>200°C) and can reach a COP of up to 1.8, making them ideal for industrial applications.

The advantages of VAM chillers include reduced electricity consumption, elimination of environmentally harmful refrigerants (CFCs, HFCs), low operating noise, and high energy efficiency, making them particularly useful in pharmaceutical plants, power generation facilities, data centers, hospitals, and district cooling systems. They are widely adopted in process cooling applications where waste heat recovery is essential for sustainable operations, making them a preferred choice in industries aiming for energy efficiency, cost savings, and reduced carbon footprint.