Clean Room Solutions

Cooling You Can Count On

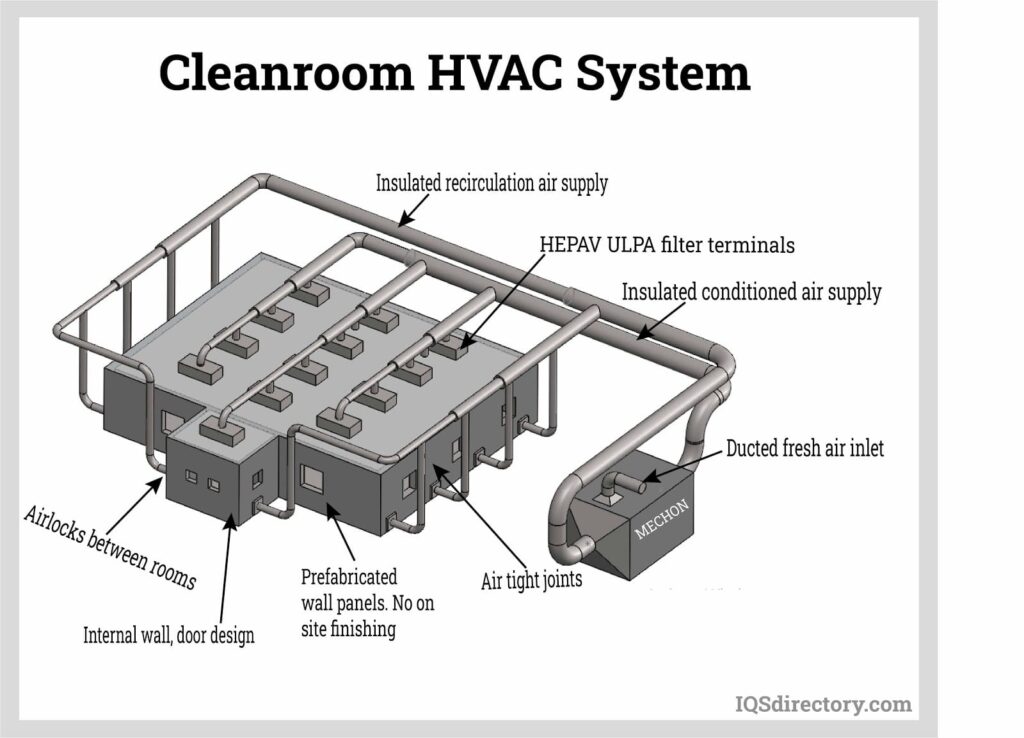

Clean room HVAC solutions are specialized air handling and filtration systems designed to maintain controlled environments with strict regulation of temperature, humidity, airflow, air pressure, and particle concentration. Industries such as pharmaceuticals, biotechnology, semiconductor manufacturing, aerospace, and healthcare rely on these systems to prevent contamination, ensuring compliance with ISO 14644, GMP, FDA, and USP 797/800 standards.

Your Comfort, Our Mission

A well-designed clean room HVAC system integrates multi-stage filtration, including pre-filters, HEPA (High-Efficiency Particulate Air) filters, and ULPA (Ultra-Low Penetration Air) filters to eliminate microscopic contaminants. These filters, combined with laminar airflow systems and controlled air pressure differentials, ensure continuous removal of particulates and microorganisms. Air changes per hour (ACH) vary based on classification, ranging from 15 ACH in ISO Class 8 rooms to over 600 ACH in ISO Class 1 environments. Advanced air handling units (AHUs), fan filter units (FFUs), and high-efficiency ductwork play a critical role in maintaining compliance with clean room standards.

Proper airflow design is essential to contamination control. Unidirectional (laminar) airflow is used in high-purity environments like semiconductor fabs and pharmaceutical filling areas, while non-unidirectional (turbulent) airflow is suitable for ISO Class 7 and 8 clean rooms. Positive pressure clean rooms prevent external contaminants from entering, whereas negative pressure rooms, used in biosafety labs, contain hazardous substances.

Air Conditioning & Heating Services

Comprehensive system scan, fault detection, detailed report, and recommended solutions. Tha Precision calibration services to ensure your air conditioning system is operating at its optimal settings for maximum comfort and efficiency

We help you with the dedication & affection

Thorough cleaning services to remove dirt, dust, and debris from your air conditioning system, improving air quality and system efficiency

How often should I have my air conditioner serviced?

It is recommended to service your air conditioner at least once a year to ensure it runs efficiently and effectively. Common signs include unusual noises, weak airflow, warm air instead of cool, and a sudden increase in energy bills.

What are the signs that my air conditioner needs repair?

It is recommended to service your air conditioner at least once a year to ensure it runs efficiently and effectively. Common signs include unusual noises, weak airflow, warm air instead of cool, and a sudden increase in energy bills.

How can I improve the efficiency of my air conditionin

It is recommended to service your air conditioner at least once a year to ensure it runs efficiently and effectively. Common signs include unusual noises, weak airflow, warm air instead of cool, and a sudden increase in energy bills.

What size air conditioner do I need for my home?

It is recommended to service your air conditioner at least once a year to ensure it runs efficiently and effectively. Common signs include unusual noises, weak airflow, warm air instead of cool, and a sudden increase in energy bills.

Categories

Ask Question

Clean room HVAC solutions are specialized air handling and filtration systems designed to maintain controlled environments with strict regulation of temperature, humidity, airflow, air pressure, and particle concentration. Industries such as pharmaceuticals, biotechnology, semiconductor manufacturing, aerospace, and healthcare rely on these systems to prevent contamination, ensuring compliance with ISO 14644, GMP, FDA, and USP 797/800 standards.

A well-designed clean room HVAC system integrates multi-stage filtration, including pre-filters, HEPA (High-Efficiency Particulate Air) filters, and ULPA (Ultra-Low Penetration Air) filters to eliminate microscopic contaminants. These filters, combined with laminar airflow systems and controlled air pressure differentials, ensure continuous removal of particulates and microorganisms. Air changes per hour (ACH) vary based on classification, ranging from 15 ACH in ISO Class 8 rooms to over 600 ACH in ISO Class 1 environments. Advanced air handling units (AHUs), fan filter units (FFUs), and high-efficiency ductwork play a critical role in maintaining compliance with clean room standards. Proper airflow design is essential to contamination control. Unidirectional (laminar) airflow is used in high-purity environments like semiconductor fabs and pharmaceutical filling areas, while non-unidirectional (turbulent) airflow is suitable for ISO Class 7 and 8 clean rooms. Positive pressure clean rooms prevent external contaminants from entering, whereas negative pressure rooms, used in biosafety labs, contain hazardous substances.

Temperature and humidity control are equally crucial, preventing microbial growth, static buildup, and material degradation. HVAC systems maintain temperature fluctuations within ±0.5°C and relative humidity (RH) between 30-60%, depending on application needs. Precision cooling, desiccant dehumidification, and advanced air conditioning technologies are employed to ensure optimal climate conditions.

To sustain performance and compliance, clean room HVAC solutions incorporate real-time monitoring and automation. Particle counters, differential pressure sensors, and Building Management Systems (BMS) provide continuous environmental tracking and automatic adjustments. Regular HEPA filter integrity testing, airflow visualization studies, and pressure differential validation ensure adherence to ASHRAE, ISO, and FDA standards. A well-engineered clean room HVAC system guarantees contamination control, regulatory compliance, and energy efficiency. By leveraging advanced filtration, air handling, and monitoring technologies, HVAC contractors can deliver superior solutions tailored to highly controlled environments.